How Glass Bottles and Jars are Made

Post time: Oct-04-2023

Glass bottles and jars are ubiquitous in our daily lives, holding everything from beverages to preserves. But have you ever wondered how these containers are made? The process of creating glass bottles and jars is a fascinating blend of art and science, involving intricate steps that result in the creation of functional and aesthetically pleasing products. In this article, we'll take a closer look at how glass bottles and jars are manufactured.

1. Raw Materials

The primary raw materials for glass production are sand (silica), soda ash, and limestone. These materials are carefully measured and mixed to create what is known as batch. Additional materials, such as alumina, may be added to enhance the glass's properties for specific applications.

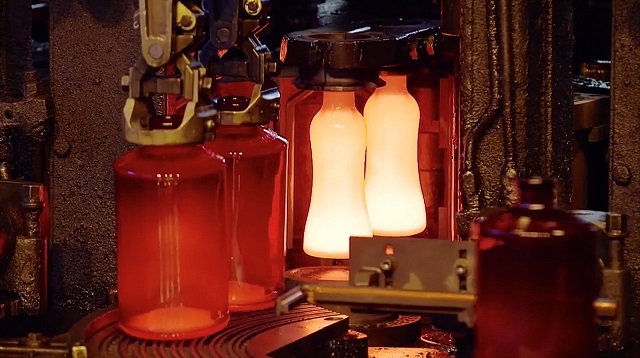

2. Melting

The batch mixture is fed into a furnace, where it is heated to extremely high temperatures, typically around 1700°C (3092°F). At these temperatures, the raw materials melt and fuse together to form a molten glass-like liquid.

3. Forming

The molten glass is then shaped into bottles or jars using one of several forming methods:

a. Blow and Blow Process: In this method, a gob (a mass of molten glass) is dropped into a mold, and a metal blowpipe is used to blow air into the gob, forcing it to expand and take the shape of the mold.

b. Press and Blow Process: This process starts with a gob being formed in a similar way to the blow and blow process. However, instead of blowing air into the gob, it is pressed against the sides of the mold to create the desired shape.

c. Blow and Blow and Blow Process: A combination of the above two methods, this process involves multiple steps of blowing and pressing to achieve the final shape.

d. Narrow Neck Press and Blow Process: Typically used for bottles with narrow necks, this method involves forming the body of the bottle using the press and blow process and then forming the neck separately.

4. Annealing

After forming, the bottles or jars are transferred to an annealing oven. This is a crucial step to relieve internal stresses in the glass caused by the forming process. The containers are slowly cooled over a period of several hours to room temperature to ensure they have uniform strength and durability.

5. Inspection

Quality control is paramount in glass manufacturing. The bottles and jars undergo rigorous inspection processes to check for imperfections, such as bubbles, cracks, or uneven thickness. Automated systems and skilled technicians ensure that only the highest-quality containers move on to the next stage.

6. Surface Treatment and Decoration

Once the containers have passed inspection, they can undergo surface treatments or decoration as required. This may include frosting, labeling, screen printing, or embossing to give the bottles and jars their unique appearance.

7. Packaging

The final step in the manufacturing process involves packaging the glass containers for distribution. They are carefully sorted, stacked, and packed in cartons or pallets to ensure safe transport to their intended destinations.

The production of glass bottles and jars is a complex and precise process that combines the artistry of glassblowing with the science of materials engineering. The result is a wide array of beautifully crafted containers that serve a multitude of purposes in our daily lives. Next time you enjoy a refreshing drink or savor homemade preserves, take a moment to appreciate the craftsmanship and ingenuity that went into creating the glass bottle or jar that holds your favorite product.